How to Install PVC Interlocking Floor Tiles: A Step-by-Step Guide

When it comes to industrial flooring, you want a solution that is robust, durable, quick, and easy to install. The PVC Interlocking Floor Tiles Installation by Camp Manufacturing are a one-stop solution for all your industrial flooring needs in India. This comprehensive guide’ll walk you through the step-by-step floor tiles installation process, ensuring your facility is up and running quickly.

Unopened Box of Camp Manufacturing PVC Interlocking Tiles Ready for Installation

Why Choose PVC Interlocking Floor Tiles by Camp Manufacturing?

Before diving into the floor tiles installation process, it’s essential to understand why these tiles are increasingly becoming the choice for professionals in the industrial sector.

Durability: These tiles are designed to withstand heavy machinery, chemical spills, and the rough and tumble of industrial environments.

Ease of Floor Tiles Installation: One of the key benefits of our Floor Tiles Installation of PVC interlocking tiles is the hassle-free and quick installation process.

Necessary Tools and Materials for floor tiles Installation

To prepare for the Floor Tiles Installation of PVC Interlocking Floor Tiles by Camp Manufacturing, it’s crucial to gather all the necessary tools and materials beforehand. The right tools will streamline the process and help you achieve professional-grade results. Below is a list of what you’ll need, along with an explanation for each:

1. Rubber Mallet

Purpose: The rubber mallet gently taps the tiles into place, ensuring a snug fit without damaging the material.

Why It’s Essential: Unlike a standard hammer, a rubber mallet delivers a softer impact, helping to protect the integrity of the interlocking mechanism and the tile surface.

2. Measuring Tape

Purpose: The measuring tape is needed to measure the area where you’ll install the tiles accurately. This ensures you have enough material and helps in planning the layout.

Why It’s Essential: Proper measurement is critical to optimising tile usage and minimising waste. It also helps you anticipate challenges, like handling corners or obstacles, before laying the tiles.

3. Utility Knife

Purpose: The utility knife cuts the tiles to fit the room’s dimensions, particularly around the edges and corners.

Why It’s Essential: A sharp utility knife allows for precise cuts, ensuring the tiles fit perfectly into any space, big or small. This is especially useful for custom fitting around objects or irregularly shaped areas.

Preparing the Floor

Clean the Surface: Ensure the floor is clean and free from debris.

Inspect for Damages: Check for any cracks or irregularities in the floor.

Preparing the Industrial Floor for PVC Floor Tiles Installation

Detailed Floor Tiles Installation Steps

Step 1: Layout Planning

Select the Starting Corner: It’s essential to start installing from one corner of the room. Decide on the corner based on your floor layout.

Orientation of Tiles: Decide the direction you want the tiles to go. Typically, aligning the tiles with the longest wall gives a balanced look.

Planning the Layout for PVC Interlocking Floor Tiles Installation

Step 2: Begin Laying the Tiles

Place the First Tile: Start by placing the first tile so that its edges align with the corner’s two walls.

Check Alignment: Use a carpenter’s square or another right-angle tool to ensure the tile is perfectly aligned with both walls.

Step 3: Interlocking the Tiles

Position the Next Tile: Align the following tile so that the interlocking edges match the first tile.

Use a Rubber Mallet: Gently but firmly, use a rubber mallet to tap the tiles so they interlock securely. Ensure you hear a click sound, ensuring the tiles are correctly interlocked.

Using Rubber Mallet for Interlocking PVC Tiles

Step 4: Continuing the First Row

Follow the Same Method: Continue placing tiles alongside the first tile, following the alignment and interlocking procedure until the first row is completed.

Check for Straightness: Frequently use a straight edge or laser level to ensure the tiles are laid straight.

Step 5: Starting New Rows

Stagger the Joints: Start the next row with a tile cut in half to increase stability and improve aesthetics. This will stagger the joints, similar to a brick pattern.

Continue Laying Tiles: Complete the subsequent rows following the same procedures as earlier, keeping everything aligned and interlocked.

Step 6: Cutting the Tiles for Edges and Corners

Measure the Gap: For the tiles along the edges and corners, measure the remaining gap carefully.

Mark and Cut: Mark these measurements on a tile and then use a sharp utility knife to cut along the mark carefully.

Cutting PVC Tiles for Edges and Corners

Step 7: Final Inspection and Finishing Touches

Inspect Each Tile: Walk around the room to ensure all tiles are securely interlocked.

Apply Finishing Edges: If your kit includes edge pieces, attach these along the perimeter for a clean finish.

Addressing User Needs

Durability and Longevity

Robust Material: The high-quality PVC in these tiles ensures they are tough and resilient. This translates to fewer replacements over time, resulting in cost savings and reduced material waste.

Traffic Resistance: Be it high foot traffic or heavy machinery, these tiles can withstand significant wear and tear, making them ideal for industrial environments.

Safety and Ergonomics

Anti-Slip Surface: The tiles come with anti-slip properties, reducing the likelihood of workplace accidents.

Ergonomic Design: The comfortable surface of these tiles makes standing and walking easier on the feet, a must-have feature for facilities where employees are on their feet for extended periods.

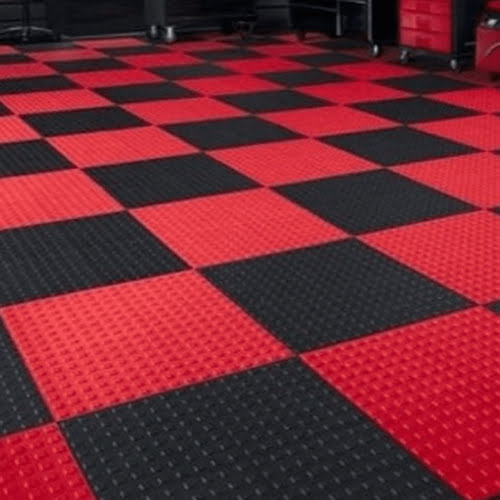

Customizability

Flexible Design Options: You can choose from a range of colours and textures to match the aesthetic of your facility.

Scalability: As your business grows, it’s easy to scale your flooring by adding more tiles, thanks to the simple interlocking system.

Industrial Applications

Manufacturing Plants

Resistance to Chemicals: These tiles resist corrosive chemicals, making them suitable for manufacturing environments where such substances are prevalent.

Ease of Maintenance: Easy to clean and maintain, these tiles are perfect for facilities that need quick turnarounds between shifts.

Renewable Energy Plants

Insulating Properties: The PVC interlocking tiles offer good insulation properties, crucial for energy plants where electrical conductivity can be a concern.

Environmental Benefits: Given that renewable energy plants are at the forefront of sustainability, using environmentally-friendly flooring like these PVC tiles sends a consistent message.

Food Processing Industries

Hygiene and Safety: The tiles are easy to clean and disinfect, a crucial factor in food processing.

Recyclability: Align your food processing plant’s sustainability goals with these recyclable tiles.

Automotive Industry

Heavy-Duty Use: Can withstand the heavy machinery and equipment used in automotive assembly lines.

Chemical and Oil Resistance: These tiles resist automotive fluids, making them ideal for this industry.

PVC Tiles in Different Industrial Settings

FAQs

How Do PVC Interlocking Floor Tiles Compare to Traditional Flooring Options in Terms of Durability?

Answer: PVC Interlocking Floor Tiles by Camp Manufacturing are designed to offer robust durability, capable of withstanding high traffic and heavy machinery usage. Unlike traditional flooring like concrete or epoxy, which may require frequent maintenance or replacement, our PVC tiles are long-lasting, making them a cost-effective and reliable option.

Are These Tiles Suitable for Outdoor Applications?

Answer: Our PVC interlocking tiles are primarily designed for indoor industrial use. However, they are water-resistant and can tolerate mild outdoor conditions. Consulting with our team for more customised solutions is best for specialised outdoor applications.

What Measures Are Taken to Ensure the Tiles Are Eco-Friendly?

Answer: Sustainability is at the core of our product design. The tiles are manufactured using an energy-efficient process and are fully recyclable at the end of their lifecycle. They are also made from high-quality, non-toxic materials, ensuring environmental safety and human health.

Can I Install These Tiles Myself, or Do I Need Professional Assistance?

Answer: One of the advantages of our PVC interlocking floor tiles is their easy and quick installation process. You can certainly install them yourself using our step-by-step guide. However, for large-scale or specialised in Floor Tiles Installation, professional assistance is recommended for optimal results.

Do You Offer Customized Solutions for Specific Industry Needs?

Answer: Absolutely! We understand that each industry has its unique challenges and requirements. Our team can consult you on customised solutions, from selecting the appropriate colour and texture to unique features like anti-static properties to meet your needs.

Conclusion

With the rising demands of modern industrial settings, PVC Interlocking Floor Tiles by Camp Manufacturing provide unparalleled robustness, aesthetic flexibility, and ease of installation. This step-by-step guide aims to make the installation process as straightforward as possible, ensuring that your industrial flooring is functional and ready for anything.