The Role of Advanced Materials in Custom Plastic Parts: Unveiling CAMP’s Mastery

“In the domain of sophisticated custom plastic components, the mastery lies in the material. Rigorous engineering thermoplastics, molded PVC, and rubber profiles will clarify this misconception.”

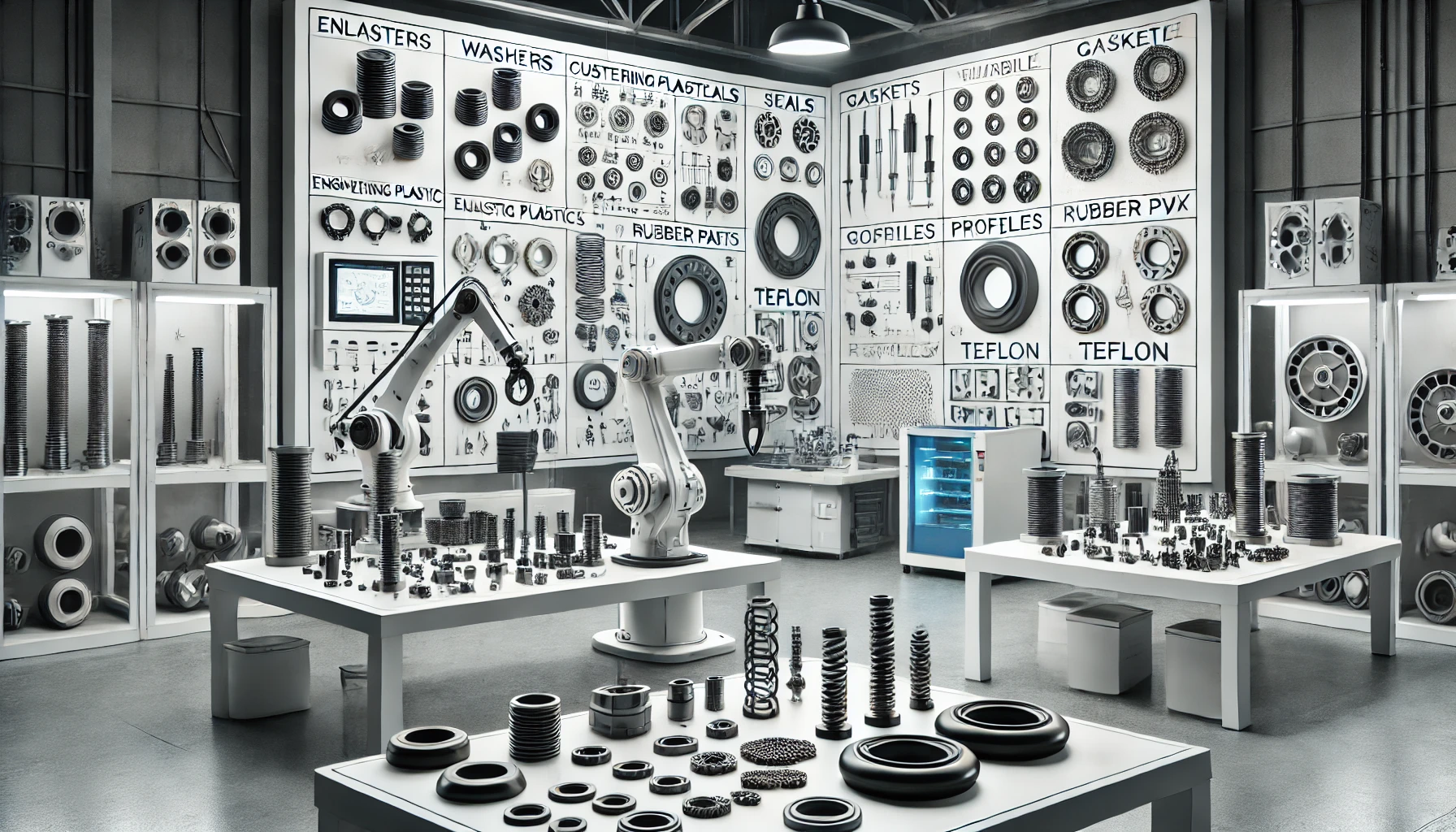

In the ever-evolving world of industrial manufacturing, the material used in a product is not just a part of the process; it’s the heart of innovation. At Create All Machined Parts (CAMP), we understand this better than anyone. When it comes to custom plastic parts, the material choice is not just a decision—it’s a statement about quality, durability, and innovation.

The Importance of Material Selection in Custom Plastic Parts

CAMP strives to place forth unquestionable value for the money. Is that all it takes to value accurate engineering thermoplastics? When it comes to the parts, yes. Even a single slack on the right material will be catastrophic and result in maximum loss of time, cost, and resources in the case of servicing overpriced machinery. Increasing productivity should be the only step needed toward the correct material. In that case, simultaneous heating and chemicals seem to add flexibility and resistance.

These materials do improve the strength and enhance the pliability of the components. How exactly? It reduces the thermal expansion rate while also increasing the friction heat, ultimately optimizing strength while improving flexibility.

Custom plastic parts have unique requirements for different projects which are unlike any other. Whether it’s a component for a high-speed automotive application or a part exposed to harsh chemical environments, each heuristic demands focus with a material that can withstand those obstacles. CAMP shines where expertise is required. We don’t just choose materials; we rather pick them according to project requirements.

Engineering Plastics: The Backbone of Customization

Meet engineering plastics, the durable forms of plastic. It’s formed with a purpose of enhancing coping with tough conditions such as high and low temperatures alongside mechanical stress. These are not like everyday plastics, they are tougher and superior. Engineering plastics make versatility easier with custom applications and sustain harsh environments like harsh chemicals.

CAMP uses engineering plastic to customize parts with specifications provided by the client which in return strengthens the engineering side. For instance, custom nylon washers with superb thermal and wear resistance along with strength. That’s always the case with dirty performing washers. Nylon as an engineering plastic gets the job done effortlessly under the most stressing conditions.

But don’t just take our word for it. Think about how we aided a leading automotive manufacturer. In their new line of high-performance engines, they required washers that normal ones could not perform in. Custom nylon washers were required, and not only did our washers perform to their expectations, but they also enhanced performance by adding to the efficiency and reliability of the engines.

Molded PVC: Versatile and Durable

Molded PVC, or Polyvinyl Chloride, is arguably the strongest of the family of plastics. It is revered for how tough, flexible, and adaptable it is. This material is known to resist chemicals as well as weather and general wear and tear. It is also well loved because of its adaptability, it can be molded into practically any shape.

For us at CAMP, molded PVC represents a new frontier to innovate and use our creativity. We design and manufacture custom parts out of it, which are not only strong components, but are also exactly what the clients require. From small parts to large industrial devices, we manufacture molded PVC products tailored for all our clients’ requirements.

Where can you observe these PVC wonders in use? In construction, they feature in window frames and pipes, while in healthcare, they transform to medical equipment. Even in your car, there might be parts made of molded PVC. Their versatility allows them to be used in many industries.

Rubber Profiles: Flexibility Meets Durability

Let us now focus on rubber profiles. They’re like flexible friends in the material world. In their day-to-day life, rubber profiles are used for seals and gaskets that are subjected to pressure. This profile is the epitome of bending without breaking.

Rubber behaves a certain way, and at CAMP, we make sure to understand that. Combining our expertise in rubber fabrication with engineering, we design custom parts that are not only flexible but long-lasting. It’s like making a puzzle piece that fits exactly where it’s needed.

What about these rubber wonders? For starters, you can find them in cars, sealing doors and windows. In machines, they act as leak proof containers, and even in buildings, helping to keep them insulated. Simple as rubber, but without these profiles, functioning would be chaotic.

Custom Teflon Parts: Sliding into High Performance

Aside from its prominent use in making pans non-sticky, Teflon also excels as a custom part material. Teflon’s special abilities make it an outstanding candidate for custom parts because it is tough against heat and chemicals, meaning things slide over it without getting stuck.

At CAMP, we utilize Teflon’s superpowers for parts that require extreme sliding and enduring difficult conditions. We specialize in creating tailored parts that help our clients tackle unique challenges—what we like to call ‘Teflon tailoring’ projects.

Where do these Teflon parts show off their skills? In machines where parts move frequently, enabling them to avoid wear and tear. When heat or aggressive chemicals are prevalent, Teflon parts are required to ensure everything runs smoothly, like a non-sticky, well-oiled machine.

Quality Assurance: The CAMP Promise

At CAMP, we don’t just manufacture parts; we guarantee quality. With strict self-imposed quality control standards, we focus on every single detail and ensure perfection in all parts. This meticulous attention to detail transforms the CAMP guarantee into a superpower. Instead of striving to achieve standards, we exceed them.

Quality control is how we monitor the production of each custom plastic part to assure it’s quality meets standards. Picture it like watching over the process, a guardian angel if you will, during production. We ensure that everything is checked and double-checked, right from the initial sketch to the final product. Because we do this, our parts are reliable, durable, and precise to what our customers intend them to be.

Tailoring Solutions: CAMP’s Approach to Customization

CAMP directly collaborates with customers to identify their needs. Broadly, we pride ourselves on responsiveness to specific needs and tailoring solutions based on client requirements.

Individual clients have different requirements and at CAMP, we make sure to make note of each individual customer’s requirements. This means we listen and put in the required effort. Our processes are diverse and unlike other manufacturers. Designing parts starts by taking what the customer provides and our guidance to tailor the perfect solution. It’s like making a custom tailored plastic suit. It is unique, fits perfectly, and uses our expertise alongside the client’s needs.

The design and manufacturing is a blend of science and art for us. While we have the latest technological advancements, we also incorporate human interaction. A lot of collaboration happens with our experts and clients which includes guiding the client step by step from the idea stage to the final product. And by working together, we’re able to explore to find the best solution.

Conclusion

To sum up, CAMP is not just a custom plastic parts manufacturer; it is a revolution all on its own. With years of unparalleled dedication and commitment, we combine quality assurance and custom services with advanced materials such as engineering plastics, molded PVC, rubber profiles, and Teflon. Our local knowledge and global reach ensure that we can tackle any issue and provide not only parts but also relief.

With this final conclusion, we encourage our customers and clients to familiarize themselves with what’s on offer. Whether you’re trying to complete a project and need a custom part or you’re trying to find a solution to a manufacturing problem, we are always at your service. Choose CAMP and get ready to dive into a pool of innovation, quality, and custom solutions.