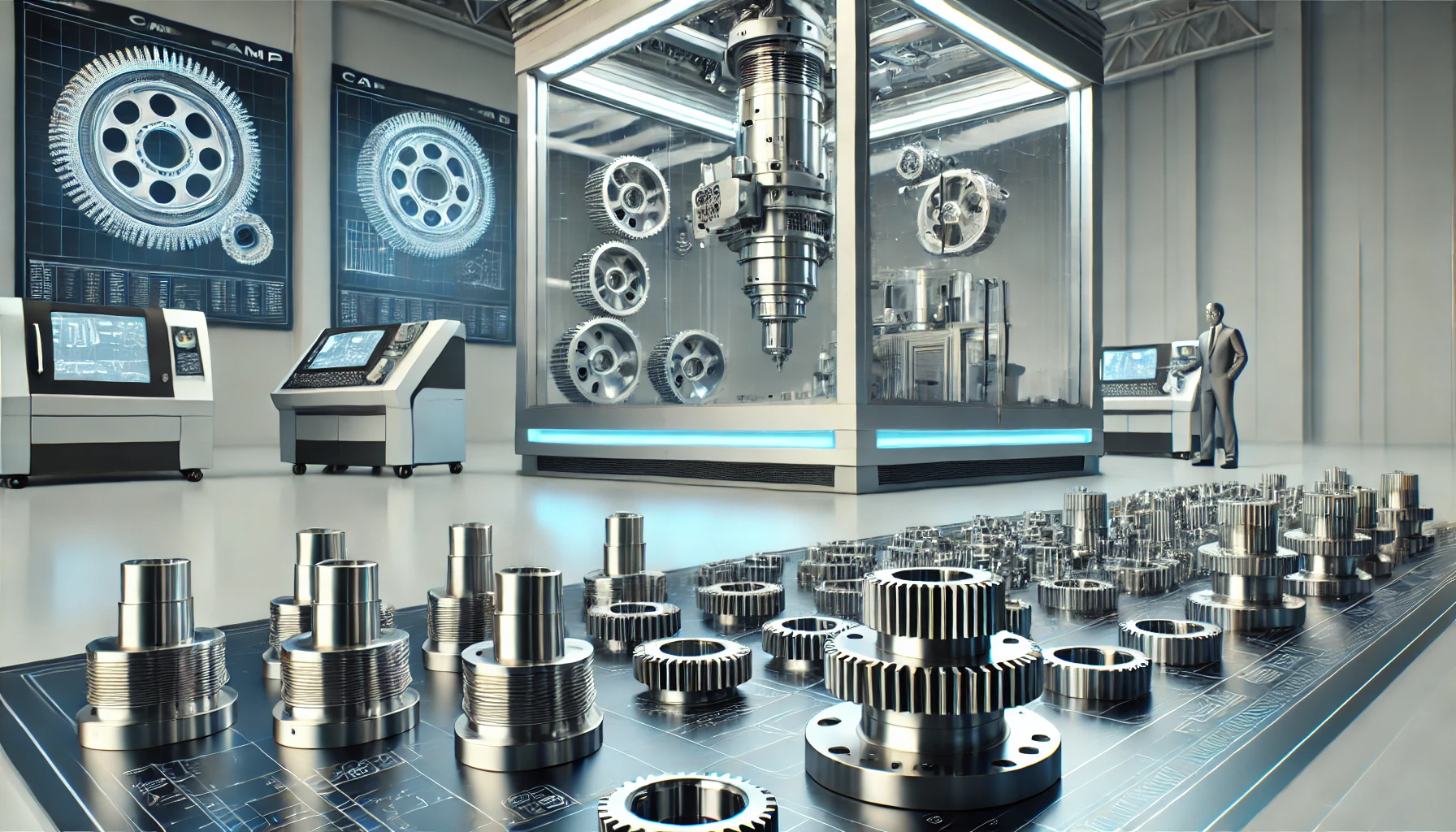

Metal Machined Parts by CAMP: Precision Engineering and Manufacturing Mastery

“Did you know that the secret to unmatched precision in the world of manufacturing lies in the art of metal machining? Let’s bust some myths and unveil the facts about the precision engineering and technology behind CAMP’s metal machined parts.

A variety of industries, ranging from aerospace to oil and gas, necessitate the development of specific parts, so there is an ever-growing demand for further precision in metal machining. The procedures involved in creating processes have led to the advancement of civilization. How does an organization such as CAMP keep up with these changes? How does CAMP stay in sync with modern engineering technologies and requirements? Let’s tell you the story of metal machining that differs from the rest in every way.

The Art of Metal Machining: An Overview

Metal machining is the process of shaping metal into specific, precise parts. Think of it like sculpting, but instead of clay, we use metals. This process involves cutting, drilling, milling, and turning metal using various tools and machines. The goal? To produce parts that fit specific dimensions and purposes, down to the smallest detail.

A lot has changed in metal machining throughout the years. It’s no longer the same as manual labor work. Nowadays, technology is at the center of everything. The introduction of computer numerical control (CNC) technology and machinery has considerably improved the level of accuracy and efficiency in metal machining.

CAMP’s Precision Engineering: A Cut Above the Rest

At CAMP, precision engineering is more than just a term, it’s an integral part of our routine. Our workforce utilizes advanced precision engineering methods to manufacture metal components that are extremely accurate. Each part, from the curves to the angles and edges, is executed with extreme precision so that the set standards and requirements are precisely achieved.

What is the reasoning behind this degree of accuracy? In manufacturing, specifically for metal parts, it’s common for someone’s malfunctioning machinery or car, to put their life in danger due to a lack of precision. Within the realm of manufacturing, especially with metal parts, even the tiniest inaccuracy can have an astronomical fallout. Thus, CAMP’s professionals step in. The reality is that our parts undergo precision engineering during their creation which guarantees their accuracy and quality making them true masterpieces.

Advanced Technologies in Metal Machining at CAMP

When we mention machining of metals at CAMP, we are literally light years ahead. The CNC (Computer Numerical Control) machines form the basis of our operations. These tools are not simply machines as they can be aptly termed as the sophisticated robots that have invaded the world of machining. CNC machines cut and shape metals with unprecedented precision. This is possible because of the advanced Computer Controlled Programs that these machines are equipped with.

But why is there a need for such sophisticated machines? Imagine trying to cut a minute piece of an intricately designed component manually, not only is it difficult, but nearly impossible to get it exact. This is where CNC machines can help. No matter how complex the part, these machines can and will generate exact replicas time after time without any errors. You can understand how important precision is in the manufacturing of car and airplane parts.

Materials Matter: The Metals CAMP Works With

Here at CAMP, we don’t use any metal for machining. We analyze each job and choose the most suitable metal. As with any industry, there are materials that shine brighter than others, and here, aluminum and steel stand out. In particular, aluminum is both lightweight and strong, making it ideal for parts that require a sturdy structure but need to be light. Steel is a powerhouse because it is incredibly tough and can withstand a lot of stress.

Choosing the right metal is critical. It’s like selecting the primary ingredient in a dish. If a chef chooses the wrong element, the value of the entire recipe becomes questionable. In machining, selecting the incorrect metal can lead to a part that either wears out too fast or fails to perform adequately. This is why we dedicate a substantial amount of effort into determining the absolute best metal for every part we construct at CAMP.

Engineering Expertise: The CAMP Edge

The peculiarity that CAMP services is their team of expert engineers and machinists. These professionals are not pure operators; they are the chefs. They know everything about the engineering and science of the materials, and the art of fabricating precision parts from CAMP.

Incorporating Their Background Knowledge In Manufacturing Process. Their expertise is the missing piece for our manufacturing process. They program the CNC machines and select the appropriate metal for each particular project. With their strong knowledge and years of experience, when you receive a part from CAMP, it is not a mere piece of metal. Instead, it is the culmination of engineering mastery put into the metal with exceptional care and precision.

Quality Control in Metal Machining

CAMP has taken quality control, in metal machining discipline, to another level as it is their primary concern. Consider it as a ‘guardian’ who makes sure all the metal pieces produced are up to a certain standard. From the moment a piece of metal arrives at the facility, until it leaves as a finished product, we monitor every phase of the procedure. Multiple tests and inspections are done to ensure the piece has the right dimensions, shape, and functions correctly.

Why is this critical? Because trust lies at the heart of quality assurance. When our parts are integrated into machines or structures, they have to be significantly more than just good; they need to be perfect. Safety and performance are so deeply dependent on the reliability and durability of parts, that it becomes imperative. That’s why at CAMP, we make the firm commitment that each part we manufacture, time after time, will be able to endure even the most extreme tests.

Customization: Meeting Client-Specific Needs

At CAMP, customization is more than just a practice, it’s our strategy. As we noted before, each client comes with their own unique requirements and customization specifications. It’s like a tailor comes in to custom fit a suit; it has to fit like a glove. Our team works closely with clients to understand the specific needs, and then designs and manufactures machined metal parts with precision to those very specifics.

For instance, we had a client in the aerospace segment who needed parts that were not just extremely light, but also durable. With accuracy in material and precision engineering, we were able to revise parts that not only matched but surpassed their expectations and added impetus to their project’s success.

Global Standards, Local Manufacturing: CAMP’s Strategy

At CAMP, we have a firm focus on local manufacturing capabilities, while keeping a global perspective. This enables us to achieve Quality Control precision that allows our products to compete globally. Simultaneously, we reap the advantages of local manufacturing. Because of this, we are highly flexible with our clients and are able to provide swift responses and high quality service.

Conclusion

With advanced technologies in CAMP, along with an expert engineering team, metal machined parts will be created with utmost precision and care. Our dedication towards customization while abiding by the international norms alongside our manufacturing capabilities enables us to stand out in the global market. Thus, we walk out as leaders in this domain.

CAMP is your solution partner when it comes to meeting your needs of top-quality, precision metal parts. Let us resolve your engineering hurdles and convert them into achievements.